For the last decade, I’ve watched 3D printing grow from an incredibly niche hobby to an industry worth just under $17 billion in 2022. And while the last five years were a race to the bottom, where big brands worked to sell a consistent but not exactly easy experience in the cheapest way, the last year saw the rise of a new kind of 3D printer. These printers focus on the state of the art, offering speed, quality and ease of use instead of the lowest price tag.

Companies like AnkerMake and Bambu Lab have veered away from the open-source, build-it-yourself roots of 3D printing to offer something that the industry needs if it truly wants to attract the next 10 million buyers: a plug-and-play experience from start to finish. Those of us already entrenched in the 3D printing world might not like it, but granular, closed-source experiences are coming, and they will improve the industry.

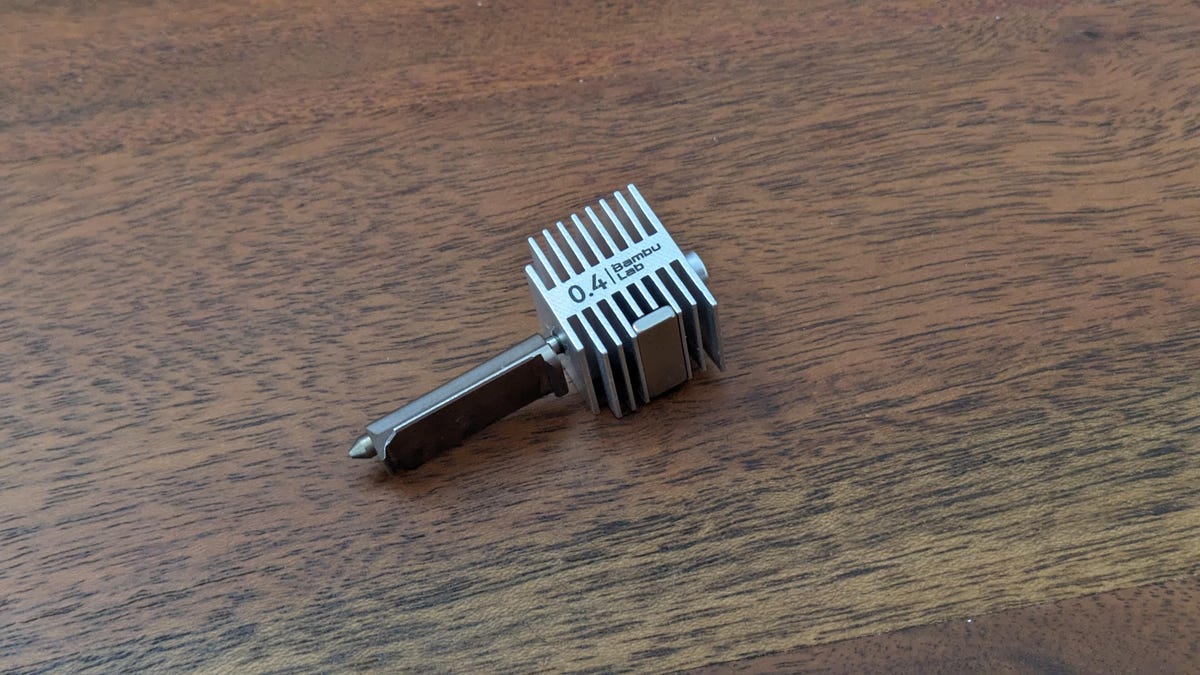

Small parts can be discarded and replaced easily.

Bambu Lab has clearly made the A1 with a complete beginner in mind. You need no prior knowledge of 3D printing to work it, and no need to learn about the inner workings if you don’t want to. Printers like this and the AnkerMake M5C are not particularly easy to tinker with, and that’s by design. The A1 is made with the fewest pain points possible and all of those pain points are easy to discard and replace. Rather than replacing individual parts of the hot end like nozzles, heat breaks and PTFE lining tubes, you simply unclip the hot end assembly and change it with a $10 replacement.

This might seem wasteful, but it’s perfectly in keeping with today’s modern technology. When your air purifier’s filter is done, you throw it out, you don’t build a new one from some gauze and plastic. That’s the same for 3D printers, or at least it should be. Consumable parts should be consumed and then replaced. I’m not saying we should be purposefully wasteful — after all, one of the defining parts of the 3D printing hobby is to make things so you don’t have to buy replacements — but we need to make the transition as easy as possible for the next group of buyers.

And the next group is coming. There are huge markets of creators out there who have the ideas, but don’t have the technical know-how to bring them to life on a 3D printer kit you have to build, or trying to figure out a piece of software that’s been shoehorned together from gum and hope. We need to cater to that audience if we want the market to grow.

Can a 3D printer be an appliance?

In a recent video, 3D printing guru Joel Telling remarked that the A1 felt like an appliance, and he’s right. He says that if “those appliances within your house don’t work, if you are under warranty, you contact the manufacturer and if you are out of warranty you contact a repair shop.”

“Household appliances aren’t, usually, consumer repair friendly,” Telling adds. Because of this, your average consumer isn’t thinking about repairing every small part themselves, or learning what each individual part of the machine they’ve bought does. They just want it to work and if it doesn’t, they want it fixed by an expert.

For more than a decade, we, the 3D printing community, have lived in an open-source world where we can splice together amazing machines from the leftover parts of other machines, and it has been awesome. But there is another group of people out there. They want to play our games too — they just don’t want to build the game first, and that’s OK. If we can cater to people who want a new dryer when one breaks, as well as to those of us who want to roll up our sleeves and take the dryer apart to fix it, then we’ll have an entire new generation of people excited to 3D print.

And who knows? Maybe if we can draw them in, they will get the bug and want to know more. And we will be here to guide them to a land of open-source goodness and the pot of golden stepper motors at the end of the rainbow.