General Motors will establish a $400 million factory in Bécancour, Quebec, Canada with POSCO Chemical to produce cathode active material for its Ultium batteries.

The car manufacturer announced a joint venture with POSCO Chemical in December 2021 and will begin construction at the site immediately. The cathode active material manufactured at the site consists of components including processed nickel, lithium, and other materials, representing roughly 40 per cent of the cost of a battery cell.

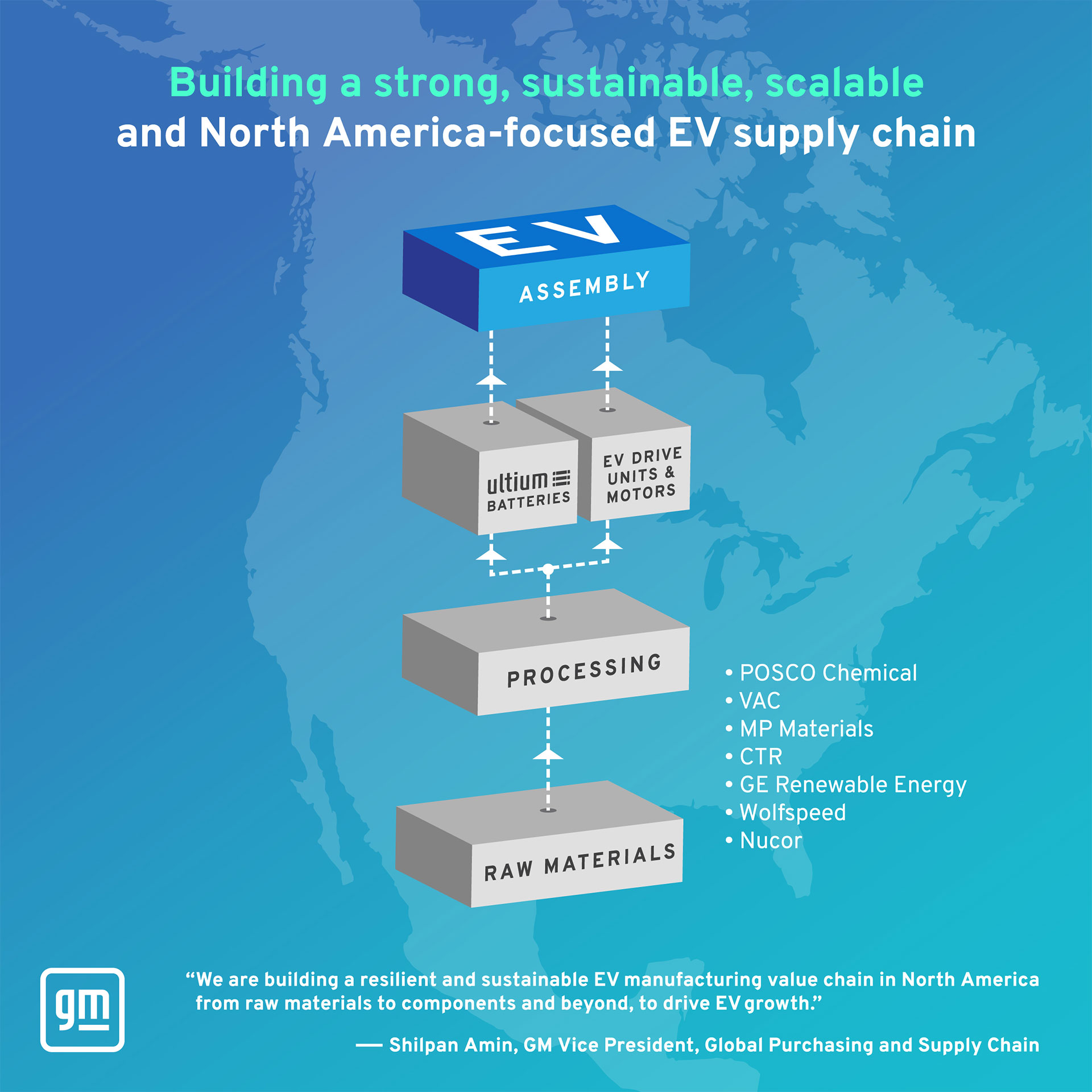

“GM and our supplier partners are creating a new, more secure and more sustainable ecosystem for EVs, built on a foundation of North American resources, technology and manufacturing expertise,” GM executive vice president of Global Product Development, Purchasing and Supply Chain, Doug Parks said in a statement. “Canada is playing an important role in our all-electric future, and we are grateful for the strong support we have received from local, provincial and national officials to grow a North American-focused EV value chain.”

Read Also: GM Investing $7 Billion In Four Sites To Accelerate EV Production In Michigan

General Motors wants to be building 1 million electric vehicles in North America by the end of 2025 and will use the cathode active material from the factory for Ultium-powered vehicles including the Chevrolet Silverado EV, GMC Hummer EV, and Cadillac Lyriq.

“It is so exciting to see GM Canada and Quebec playing a key role in building the emerging ‘mines to mobility’ EV battery ecosystem in North America,” added president and managing director of GM Canada, Scott Bell. “With this new processing facility in Bécancour, GM will help lead the EV battery supply chain while also launching Canada’s first full EV manufacturing plant in Ingersoll, Ontario, later this year.”

GM is working with other companies to secure a supply chain for EV components. For example, it is collaborating with Controlled Thermal Resources to secure lithium produced in California, will develop a rare earth value chain with GE, source alloy flakes from MP Materials, and purchase permanent magnets from VAC.