BMW’s new battery cells boost range by 30% and cut production-related carbon emissions by 60%

November 3, 2023 at 07:20

–>

–>

–>

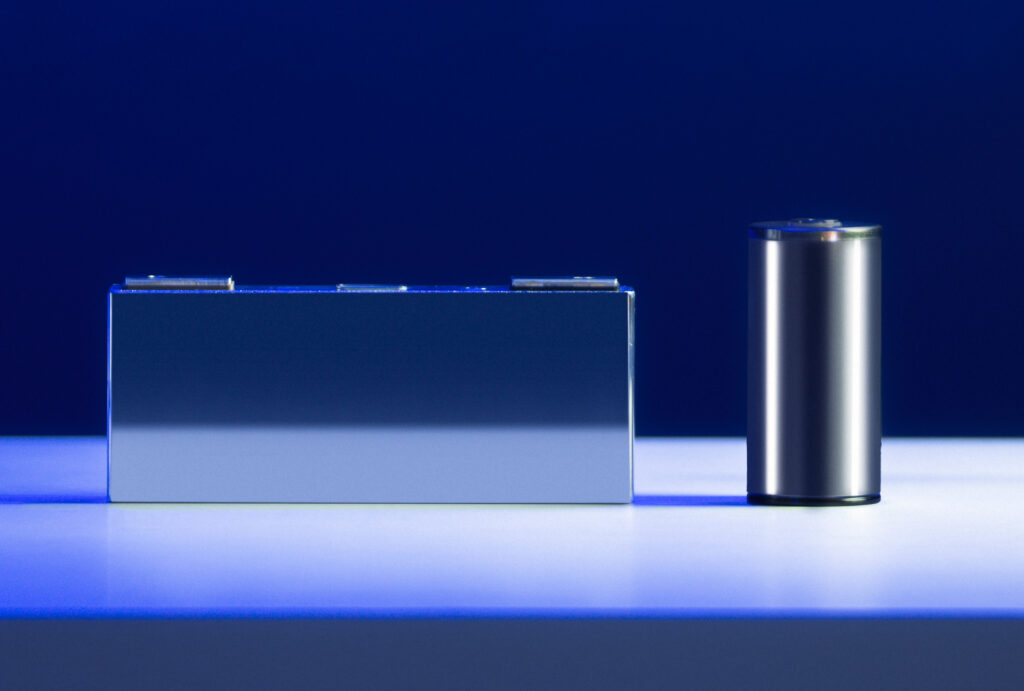

BMW believes that its newly-developed Gen 6 battery cells don’t just represent a massive leap over the prismatic cells that it currently uses but are even more advanced than the cells underpinning Tesla’s current models.

The German car manufacturer recently commenced sample production of its new battery cells at the BMW Group Cell Manufacturing Competence Center in Parsdorf, Germany. These cells will be used by BMW’s Neue Klasse-based EVs launching from 2025 and are said to represent a huge leap forward.

In fact, the new cells with a 46 mm diameter and standing either 95 mm or 120 mm tall (depending on the version) are said to provide 20% more energy density, up to 30% more range, and 60% lower production-related carbon emissions than BMW’s current cells. They will be able to give Neue Klasse models up to 500 miles (~800 km) of range. The cells have higher nickel content and lower cobalt content on the cathode side and higher silicon content on the anode side than outgoing cells.

advertisement scroll to continue

Read: BMW To Begin Producing Solid-State Battery Cells This Year

“Tesla needs to close the gap with us,” BMW Group production boss Milan Nedeljkovic told Auto News. “In fact, we don’t see a gap to Tesla… What we have here is a battery design that suits our products, and our idea of how driving performance is fulfilled in our cars.”

While development of the cells has been done at the company’s facilities, it will not handle large-scale production. According to BMW, the “high-volatility” of large-scale battery cell production will be done by suppliers Contemporary Amperex Technology Co (CATL) and Eve Energy at six different factories. Two of these factories will each be located in Europe, China, and North America.

According to Nedeljkovic, BMW is aiming to perfect the recipe of the battery cells at the Cell Manufacturing Competence Center and successfully complete sample production before giving the go-ahead to its suppliers to begin full-scale production.

“If you want to cook something really nice you need a good recipe, and the recipe determines the taste. We develop the recipe, namely the chemistry and physics of a cell. We change the content and test how each single cell ingredient will influence performance,” he described. “As the next step, you need to find a manufacturing process that matches your recipe. That’s why we have this production facility here in Parsdorf to make sure that the dish tastes as good as it should.”

–>

–>